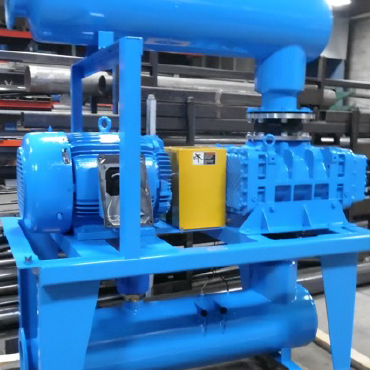

Direct Drive Advantages Over V-Belt Approach

V-belt technologies have been utilized for over 100 years and with most municipal and private wastewater treatment operations using this approach, they are viewed to be “tried and true”. However, over the past 10 years, direct-drive technology has risen to a very reliable level so as to provide a solid alternative to the former standard.

When considering a direct-drive approach, the following factors help to support the purchase of a direct-drive solution:

- No overhung load on the shafts, sheaves or bearings, thereby eliminating that extra wear and tear, and prolonging the life of these components, and the system in general, for many years.

- Better and lower energy consumption levels, providing $100s to $1000s in savings per year.

- HPA can provide you with an in-depth analysis showing a near exact cost profile.

- Higher level of efficiency through direct drive versus belt-drive (7-10% greater on average).

- Dramatically reduced maintenance requirements related to the elimination of belt changes, tightening, the purchase of replacement parts (belts, sheaves, and bearings).

- Accommodates misalignment between blower and motor, with as much as 4% discrepancy.

As a special note, during HPA’s manufacturing process, we use an alignment tool which ensures the same high level of accuracy as that required by power plant operators. We also provide reports that stipulate the accuracy of our alignment efforts.

All of these factors combine to dramatically reduce the risks associated with a direct-drive solution while providing strong incentives for the use of this technology and can be the perfect solution for your operation.

In utilizing a direct-drive approach, you will be engaging in a “Risk Avoidance” methodology whereby your systems will not the following scenarios:

- Elimination of blower rebuilds due to bearing failures as a result of overhung loads

- Overheating due to broken belt scenarios (where the motor continues to operate without belts)

- Out-of-compliance situations (and penalties) associated with a blower not running

With the pressures being placed on municipalities today, to contain cost, provide better services, and improve operations, there is little room for error when moving from old hardware