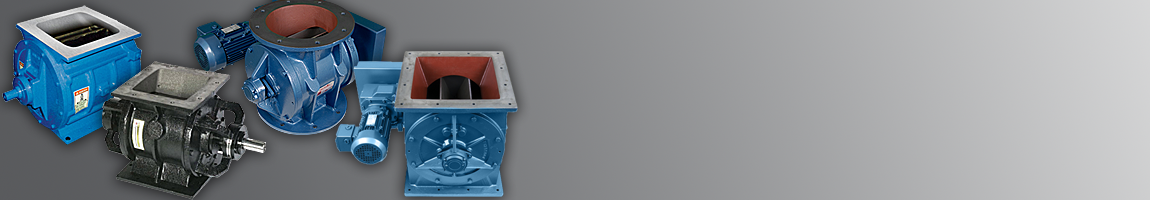

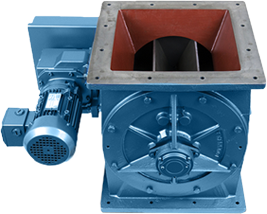

The Rotary Valve, sometimes known as the “Star Valve”, is a very important part of every material handling system. In some cases this may be used as an Airlock and in other situations it may act as a Feeder. In either case, the primary function of a rotary valve is to regulate the flow of a product, generally in dry powder or granular form, from one chamber to another while maintaining a regulated stable condition.

The materials of construction, rotor designs, special internal coatings, seal designs and internal clearances are all integral in the success of the system and longevity of the valve in the application.

With the valve serving at the heart of your system it deserves significant engineering attention. Our engineers will work with you to insure that all the questions are asked to provide you with the valve that will serve your process most effectively.

DESIGN CONSIDERATIONS START WITH…

• Housing Design

• Rotor Design

• Operating Temperature

• Desired Flow Rate

• Bulk Density of Product handled

• Differential Pressure Across Valve

• Corrosive Nature of Product

• Abrasive nature of the Product